- Could Your Grocery Store Meat Be Causing Recurring UTIs?

- Are You Making This Expensive Thermostat Error This Winter?

- Recognizing the Signs of Hypothyroidism

- 10 Strategies to Overcome Insomnia

- Could Artificial Sweeteners Be Aging the Brain Faster?

- Techniques for Soothing Your Nervous System

- Does the Water in Your House Smell Funny? Here’s Why

- Can a Daily Dose of Apple Cider Vinegar Actually Aid Weight Loss?

- 6 Health Beverages That Can Actually Spike Your Blood Sugar

- Treatment Options for Social Anxiety Disorder

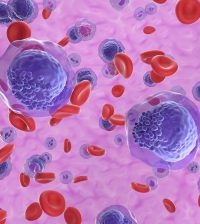

3D Printing of ‘Complex’ Human Tissue Moves Forward

Researchers report that they’ve made progress toward using 3D printing technology to produce human tissue.

The Harvard scientists say they’ve managed to create tissue in the laboratory that has vessels — potentially allowing the tissue to be fed by blood — and can survive for weeks.

Despite accomplishing that feat, scientists still aren’t close to producing human tissue that could be transplanted into the body and replace organs such as hearts and lungs, experts noted.

But Dr. Anthony Atala, a specialist who’s familiar with the study, said the new research is promising.

“It shows what can happen in the laboratory when it comes to developing human-like tissue,” Atala said, particularly when it comes to creating tissue that can be fed by bodily fluids, such as blood and plasma. Atala is director of the Wake Forest Institute for Regenerative Medicine at Wake Forest University, in Winston-Salem, N.C.

The mission: to use 3D “bioprinters” to create muscle, bone and even organ cells. So far, scientists have had some success, with the Wake Forest Institute implanting bioprinted tissue into rodents and even creating a synthetic baby-sized ear recently, Atala said.

But there are still big hurdles.

“One of the problems has been how to make tissues that don’t collapse on themselves and that are able to get nutrition in and waste products out,” said Dr. Glenn Green, an associate professor of pediatric otolaryngology at University of Michigan C.S. Mott Children’s Hospital. “Our bodies use a complex structure of blood vessels with supporting tissues to do this naturally. But large 3D-printed tissues have fallen apart or died.”

In the new study, the Harvard researchers created tissue in the laboratory that survived for more than six weeks and was “vascularized,” meaning it had vessels and could be infused with so-called growth factors, which coax cells into multiplying.

Green cautioned that the tissue won’t be ready for human testing anytime soon. Still, the existence of the vessels will allow researchers to test medications on the tissue, which will act like human tissue.

“This will markedly decrease the need for animal testing while at the same time providing more accurate predictions of how agents will affect the human body,” he explained.

As for the potential cost for patients, Atala said automation of the bioprinting process has the potential to lower expenses.

Green agreed, but he cautioned that the process to bring bioprinted tissues to the market will initially be costly.

What’s next? More research is needed. According to Green, tissues like cartilage and bone hold the most promise to be developed first, with more complex types of tissue coming down the line — muscles, then organs such as the kidney and pancreas, and then organs that have a direct connection to the brain, such as the eye.

“The eventual potential is to regenerate or replace all parts of the body,” Green said. “This paper is a nice and necessary early step on a long road.”

The Harvard study is published in the March 7 issue of the Proceedings of the National Academy of Sciences.

More information

The U.S. National Institutes of Health has more on regenerative medicine.

Source: HealthDay

Copyright © 2026 HealthDay. All rights reserved.